How to Choose the Right Woodworking Machine

Selecting the right woodworking machine is essential for efficiency, precision, and quality in your woodworking projects. Whether you're a professional craftsman or a DIY enthusiast, investing in the right equipment can make a significant difference. Here’s a comprehensive guide to help you choose the perfect woodworking machine.

1. Determine Your Needs

Understanding your specific requirements is the first step.

- Project Type: Identify the types of projects you plan to undertake (e.g., furniture making, cabinetry, decorative carving).

- Material Type: Consider the type of wood (hardwood, softwood, plywood) and other materials you'll be working with.

- Volume of Work: Evaluate whether you need a machine for occasional use or high-volume production.

2. Choose the Right Type of Machine

Different woodworking machines serve various purposes. Here are some common options:

- Table Saws: Ideal for accurate straight cuts and rip cuts.

- Planers: Used for smoothing and reducing the thickness of wood.

- Jointers: Essential for creating flat surfaces and square edges.

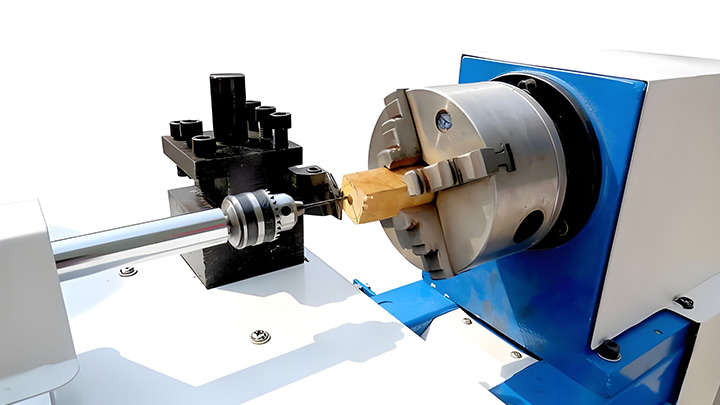

- CNC Routers: Suitable for intricate designs, carvings, and precise cutting.

- Drill Presses: Used for drilling accurate holes.

- Band Saws: Perfect for curved cuts and resawing.

3. Consider the Machine's Power and Capacity

The power and capacity of the machine should match your workload.

- Motor Power: Machines with higher horsepower are better for cutting dense hardwoods and handling heavy workloads.

- Cutting Capacity: Check the maximum width, thickness, and depth the machine can handle.

4. Prioritize Safety Features

Safety is crucial when working with woodworking machines.

- Blade Guards: Protect you from accidental contact with cutting edges.

- Emergency Stop Buttons: Allow you to quickly stop the machine in case of emergencies.

- Anti-Kickback Features: Prevent wood from being forcefully thrown back during cutting.

- Dust Collection Ports: Minimize exposure to harmful dust particles.

5. Evaluate Build Quality and Durability

Invest in a machine that can withstand long-term use.

- Material: Look for machines made from high-quality materials like cast iron or heavy-duty steel for stability and durability.

- Brand Reputation: Choose brands known for their reliability and excellent customer service.

6. Look for User-Friendly Features

Ease of use can save you time and improve the quality of your work.

- Adjustability: Machines with adjustable blades, fences, or tables allow for greater precision and flexibility.

- Controls: Intuitive controls and clear markings make operation more straightforward.

- Portability: If you need to move the machine frequently, consider lightweight or wheeled models.

7. Consider the Space Available

The size of your workshop will influence your choice.

- Compact Machines: For smaller spaces, choose compact or multi-functional machines.

- Stationary Machines: Larger, more stable machines are suitable for spacious workshops and heavy-duty work.

8. Budget Wisely

Balancing cost and quality is essential.

- Initial Cost: Set a budget and compare options within your price range.

- Long-Term Costs: Consider maintenance, replacement parts, and operational expenses.

- Used Machines: Second-hand machines can be cost-effective if inspected for wear and functionality.

9. Test Before Buying

Whenever possible, test the machine before purchasing.

- Check Performance: Assess how smoothly it runs and the precision of its cuts.

- Noise Levels: Ensure the noise level is acceptable, especially for indoor workshops.

- Vibration: Machines with minimal vibration provide better control and accuracy.

10. Research Reviews and Recommendations

Learn from the experiences of others.

- Online Reviews: Read reviews from reputable sources or forums to understand user satisfaction.

- Professional Recommendations: Seek advice from experienced woodworkers or technicians.

Conclusion

Choosing the right woodworking machine involves careful consideration of your needs, budget, and workspace. Prioritize safety, durability, and ease of use to ensure the best investment. By researching and testing machines thoroughly, you can select equipment that will elevate your woodworking projects and provide long-lasting performance.