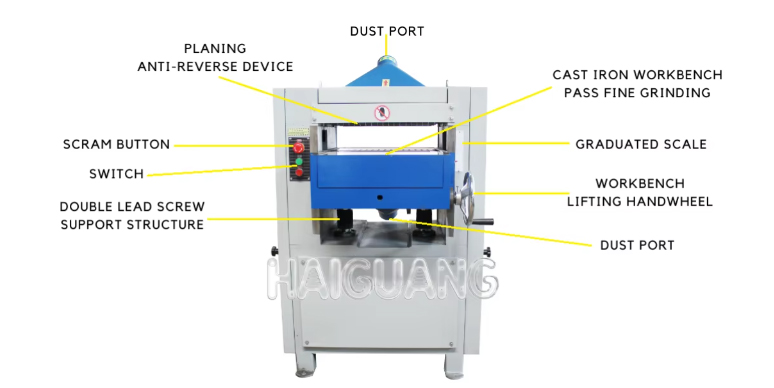

Automatic feeding, high precision, high efficiency, long service life. It is applicable to softwood, hardwood and dry wood.

The overall main body of the machine is made of ultra - thick iron plates, ensuring stability and durability.

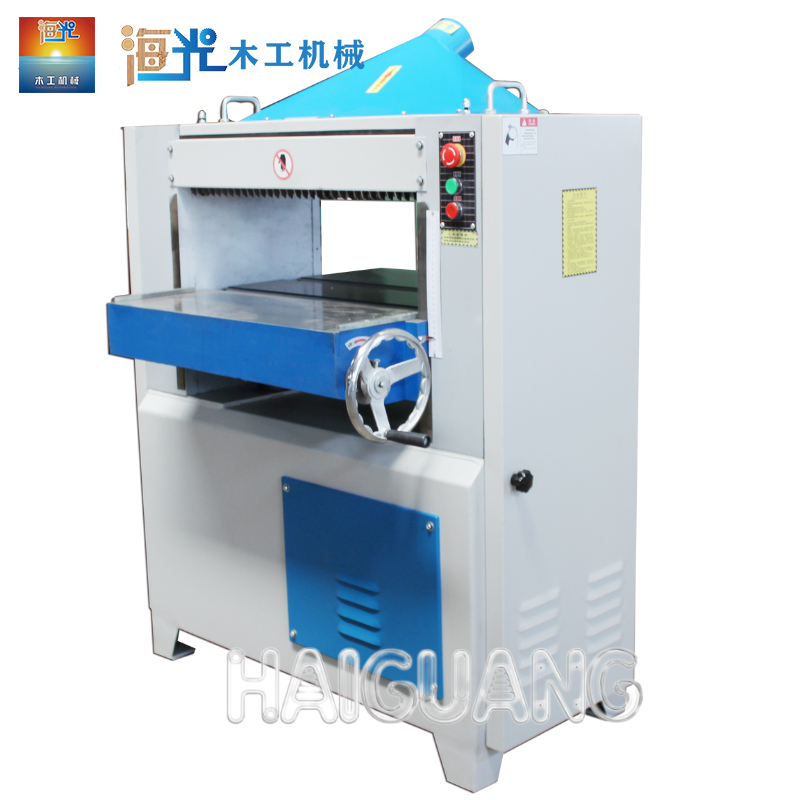

The structure consists of double feed rollers and double discharge rollers. This ensures the smooth operation of the wood and prevents damage to both ends.

With segmented feed rollers, multiple differences in wood thickness within 3 millimeters can be processed simultaneously.

The gear transmission structure features high efficiency, high precision, a strong load - bearing capacity, a long service life, high adaptability, and low maintenance costs.

It is equipped with a red emergency stop button, which is eye - catching and easy to operate. This enhances safety and reduces accidents and losses.

The planing anti - reverse device is used to prevent the material from feeding backward, ensuring continuous forward movement during the planing process and enhancing safety. The precision - ground cast - iron worktable is equipped with two feed rollers.

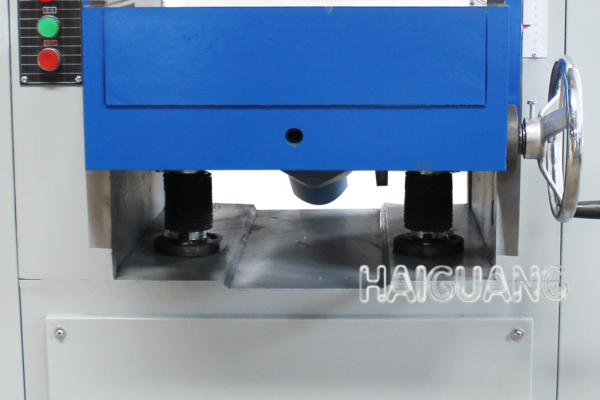

The workbench is equipped with two locking handles to increase stability.

The double - lead screw support structure has advantages such as strong load - bearing capacity and high transmission efficiency. Driven by the double - lead screws, the worktable can be smoothly lifted, ensuring precise processing of the wood.

The motor is equipped with an overload protector, which enhances safety and extends the motor's lifespan.

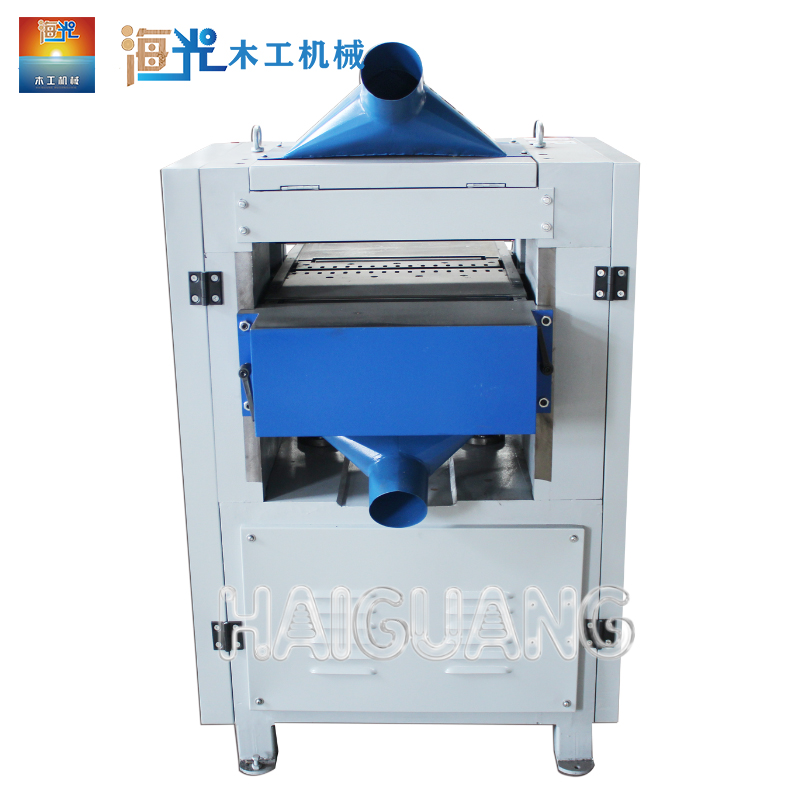

It is equipped with a dust collection cover, to which a dust collector can be connected.

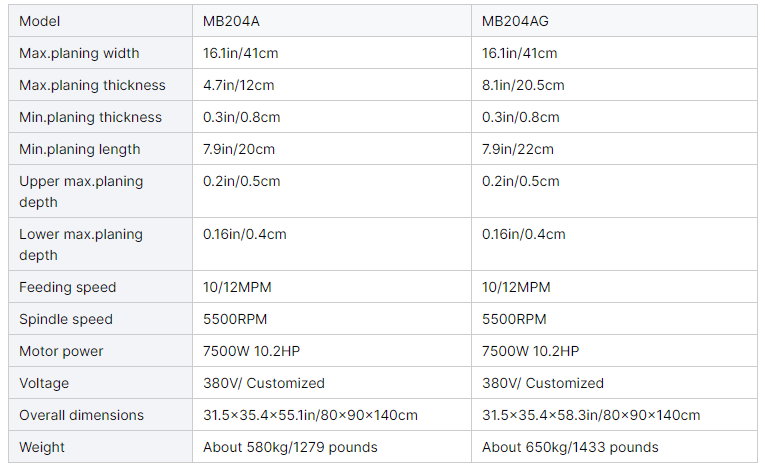

Heavy-duty Double SideWoodworking Thickness Planer

Automatic feed

High accuracy High efficiency Long service life

Suitable for Soft Wood, Hard Wood, Dry Wood

Can plane PE and PPT plates (requires replacing the carbide cutter head)

The overall body of the machine is made of super thick iron plates, which is stable and durable.

Heavier body, 580-650 kg, more stable.

Double feeding rollers and double discharging rollers structure.

Ensure smooth running of the wood and avoid damage at both ends.

With the segmented feeding rollers, multiple pieces of wood thickness difference within 3mm can be processed at the same time.

Six-helix Carbide Helical Cutterhead

Carbide Indexable Blade

No need to sharpen the knifeNo need to calibrate the knife

Planing more smooth than straight cutterhead

Gear transmission structure

High efficiency

High precision

Strong load capacity

Long service life

Strong adaptability

Low maintenance costs

Equipped with a red emergency stop button, eye-catching and easy to operate, enhances safety and reduces accidents and losses.

Planing Anti-reverse Device is used to prevent material from feeding backward, ensuring consistent forward movement and enhancing safety during the planing process.

The precision-ground cast iron workbench is equipped with two feed rollers.

The workbench is equipped with two locking handles to increase stability.

The double lead screw support structure has the advantages of strong bearing capacity and high transmission efficiency.

Through the double lead screw drive, the smooth lifting of the workbench can be realized to ensure the accurate processing of wood.

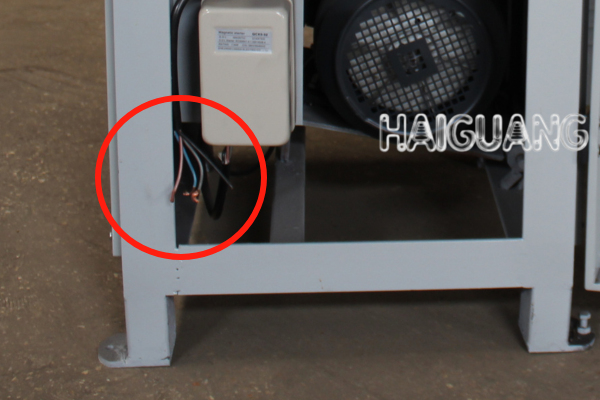

The motor is equipped with overload protector

Enhanced Safety Extended Motor Lifespan

Equipped with dust collecting covers, dust collector can be connected

Powerful Pure Copper Motor High Efficiency

Reliable

Durable

Low Noise

Long Service Life

Due to the uncertainty of the plug style and power cord length you require, this machine does not come with a plug, you will need to connect the plug and power cord yourself.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}